GREEN ROOFING SYSTEM

WELDED STAINLESS STEEL SYSTEM

(one sample layout only)

DETAIL DRAWING

Detailed Scope Of Work For New International Airport in Bangladesh-V.V.I.P.Terminal

ROOF BUILT-UP SYSTEM

(Under Tendering)

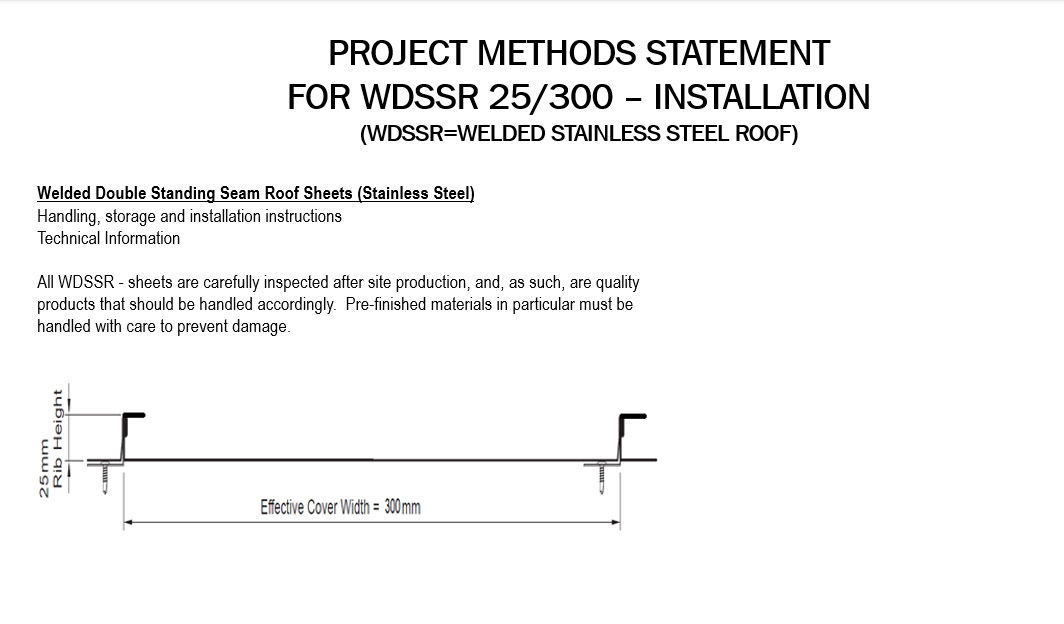

- Welded Double Standing Seam® 25/300 standing seam0.5mm thk. Stainless Steel (Welded)

- 0.8mm TCT Galvanised Corrugated Sheet

- 30mm thk. Fiberglass Insulation, density of 16kg/m3 w/black tissue

- 0.3mm thk. Aluminum Foil

- 100mm thk. Rockwool Insulation, density of 140kg/m3

- 100 x 100 x 4.0mm SHS@ 600c/c

- 2.5mm thk. Hot Dip Galvanized Plate(5mm Gap Groove)

- 1.5mm thk. Waterproofing Membrane

- 10.0mm thk. Acoustic Foam

- 2.0mm thk. Galvanized U-Channel

- 0.5mm thk. Stainless Steel Hold Down Clips

Note: Additional support steel for roof, will be by others

ROOF & FACADE CLADDING DESIGN CONSIDERATIONS

- PRINCIPLES OF BUILDING PHYSICS

- CONDENSATION

- HEAT TRANSFER

- MOISTURE PROTECTION AND VAPOUR BARRIER

- SOUND INSULATION

- SUBSTRUCTURES

Metal Roof & Façade Cladding is dependent on :-

- WORKMANSHIP

- MATERIAL –LONG TERM CORROSION RESISTANCE

- SUB-STRUCTURE

- SEAM CONFIGURATION

- DETAIL EXECUTION

- WELDING SYSTEM

ROLL FORMING MACHINE FOR STANDING SEAM METAL ROOF & FACADE CLADING

CONCEALED - FIXED & EXPANDSION CLIPS SYSTEM

What are the different types of standing seam roofing systems?

Angled Standing Seam

Double Lock Standing seam

Ledge Roof

German Industrial standard DIN Standard 18339

Eaves interface - standing seam with inclined finish

Standing seam - vertical finish

Eaves interface - standing seam (round)

SINGLE LOCK SEAMER

DOUBLE LOCK SEAMER FOR CURVE SURFACES

DOUBLE LOCK SEAMER

EAVES EDGE BENDER

Curving Machine

Seaming Machine

Bending machine

WHY METAL CLADDING?

- EFFICIENT – METAL CLADDING CAN SAVE UP TO 20% OF ANNUAL COOLING COST

- WATER TIGHT – METAL CLADDING IS DESIGN TO WITHSTAND SUN, RAIN, WIND & SNOW

- ENVIRONMENT FRIENDLY – 100% RECYCLABLE

- DURABLE - LOW MAINTENANCE

- COST EFFECTIVE – LOWER LIFE CYCLE COST

- LIGHTWEIGHT – LOWER COST OF SUPPORTING STRUCTURE

- FLEXIBILITY IN DESIGN & WIDE CHOICE OF COLOURS

- FIRE RESISTANT

- ROOFING SLOPE 0 DEGREE POSSIBLE (WELDED STAINLESS STEEL ROOF

METAL ROOF & FAÇADE CLADDING MATERIAL

- PVDF COATED ALUMINIUM & STEEL (Falzonal,Colorbond)

- INOX COLOUR STAINLESS STEEL (LIC)

- WELDED STAINLESS STEEL ROOFING

- TITANIUM ZINK

- COPPER

- TITANIUM

Why welded stainless steel roofing ?

- LOW MAINTENANCE & PERMANENTLY WEATHER PROOF

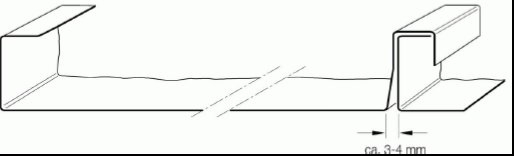

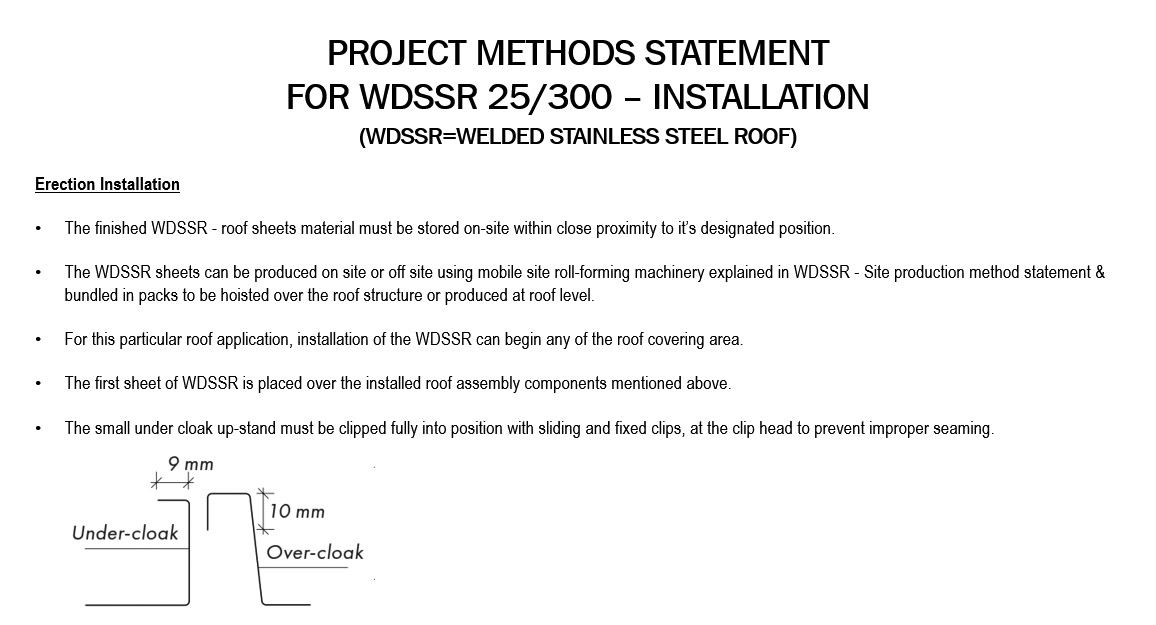

- APPEARANCE SAME AS DOUBLE STANDING SEAM BUT FULLY WELDED

- 100% WATERPROOF BY 0 DEGREE ROOF SLOPE

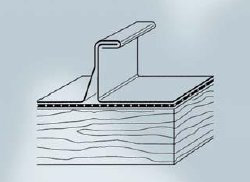

- PERFECT UNDERLAYER FOR GREEN ROOFING SYSTEM

- STAINLESS STEEL IN 445J2 ALLOY WITH 2B SURFACE,THCK.0.5MM

- ACCORDING TO EN 502;EN 508-3;EN 10088;EN 10088-2;EN 10088-3;EN 612 & EN 10088-4

- DOUBLE STANDING SEAM HEIGHT = 25MM;32MM & 50MM

- ROOFING SYSTEM ACCORDING TO EN DIN 18338 & EN DIN 18339 INCLUSIVE STAINLESS STEEL GUTTER SYSTEM

- LIFESPAN ALMOST 100 YEARS

By Others

By Others

By Others

By Others

Appearance of Welded Stainless Steel Seam

stainless steel alloy 445J2 with 2B surface

Welded Stainless Steel Roofing System

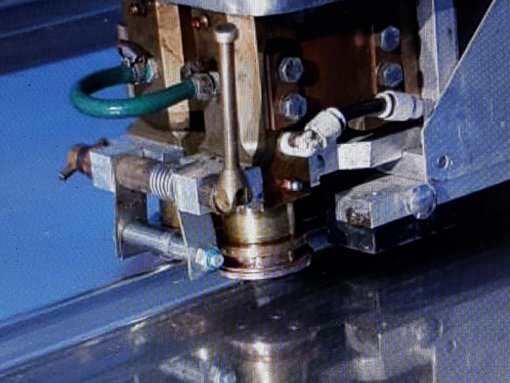

Welding Machine running along the double standing seam

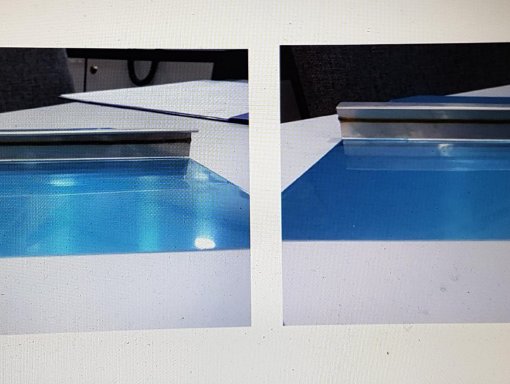

Welded Stainless Steel Roofing-dome light detail

Welded Stainless Steel Roofing-Mock up

Welding machine in progress

ROOF FABRICATION & ROLL FORMING

On-Site Fabrication: Fabricate metal roof panel on-site using portable roll-forming equipment. Fabricate according to equipment manufacturer's written instructions and to comply with details shown. Utilize roll-forming equipment configured to form panels accurately with single pass

MACHINE EQUIPMENT & TOOLS FOR WELDED STAINLESS STEEL ROOFING SYSTEM AND GREEN ROOF SYSTEM

Welding equipment for welded stainless steel roofing

a) ROOF SEAM DETAIL WELDER

- Squeeze time 0 –2000 ms

- Weld time 0 –2000 ms

- Weld power 1 –100 %

- Weld current 2.0 –4.0 kA

- Cooling time 0 –2000 ms

- Hold time * 0 –2000 ms

- Motor speed * 1 –100 %

- Calculated speed 0 –300 ms

- Current dev. 0 -25 %

- Wearing 0 –1,000 hours

- The machine must be connected to a fuse box with main switch, earth fault breaker and fuses.

- Supply Voltage: 400V/16A 3-phase 50/60Hz

- Supply Current (welding): 10A/phase **

- Welding frequency: 400Hz

- Waterflow, demand: 2 litres/minute

- Weight: 9.5kg + 17kg ***

b) ROOF SEAM MAIN WELDER

- Squeeze time 0 –2000 ms

- Weld time 0 –2000 ms

- Weld power 1 –100 %

- Weld current 2.0 –4.0 kA

- Cooling time 0 –2000 ms

- Hold time * 0 –2000 ms

- Motor speed * 1 –100 %

- Calculated speed 0 –300 ms

- Current dev. 0 -25 %

- Wearing 0 –1,000 hours

- The machine must be connected to a fuse box with main switch, earth fault breaker and fuses.

- Supply Voltage: 400V/16A 3-phase 50/60Hz

- Supply Current (welding): 10A/phase **

- Welding frequency: 400Hz

- Waterflow, requirement: 2 litres/minute

- Weight: 26kg

c) SPOT WELDER

WELDERThe technical machine data & specifications are the same as for the ROOF SEAM DETAIL WELDER & ROOF SEAM MAIN WELDER (Pos. a & Pos. b)

d) WATER CHILLER

TECHNICAL DESCRIPTION:

- Stainless steel cover

- Metal mesh air filter

- Micro-channel condenser,pure aluminum

- Water level indication ◼

- Digital thermostat with hysteresis of +/-1K◼

- Common alarm indication ◼

- Bypass for pump protection ◼

- Common alarm ◼

- Ambient temperature<42°C

HYFRA eChilly series :

- Plug and Play: -easy to install

- Compact design with micro-channel technology

- Energy efficient: less powerconsumption

- Low noise: for in-room application

- Protects the environment: 60% less refrigerant

Specification

- User-friendly interface with LCD display and master control switch, all settings is made by turning and pressing onebutton.

- Possibility to set weld power, either as percentage of transformer output or as current intensity in Ampere.

- Five weld schedules that can be individually changed and renamed with up to sixteen digits.

- Weld current monitor; with possibility to set accepted deviation in percentage, monitors secondary current and displays error message if deviates from preset set point value.

- Weld current regulation that automatically compensates for current deviations during the weld cycle. The weld is performed at a frequency of 400Hz.

- Weld log that stores the last 100 error messages, even if the machine is powered off, can be very useful introubleshooting.

- Two separately weld seam counters, one that keeps track of the total number of performed seams, and one that is possible to reset.

- Two separately time counters, one that keeps track of the total number of welded minutes, and one that is possible to reset.

Norm for Stainless Steel

- Stainless Steel Grades : EN –ASTM –BS –DIN –NF –SS

- EN Material Standarts: EN 10088-1 / EN 10088-2 / EN 10088-3 / EN 10095 / EN 10302EN 10028-7 / EN 10272 / EN 10263-5 / EN 10151

- Stainless Steel Products : P = hot rolled plate QuartoH = hot rolled strip/sheet CCC = cold rolled strip/sheetN = cold rolled narrow stripB = barR = rodSemi-finished productsTube/pipeFittingsWelding consumables

Multi-Certifications is made on request to EN / ASTM / ASME as well as to superseded national standards

EN tolerances on dimension & shape

- EN 10029 hot rolled stainless steel plate

- EN 10051 hot rolled stainless steel strips / sheets

- EN 10259 cold rolled stainless steel strips / sheets

- EN 10258 cold rolled stainless steel narrow strip

NORM FOR STAINLESS STEEL ROOFING SYSTEMS

- Welded Stainless Steel Roofing Systems in Double Standing Seam System or AngleStanding Seam.

- System according to the EN / DIN Norm 18338 & EN / DIN NORM 18339 inclusive Stainless Steel Gutter Systems.(Green Roofing Systems)

PROJECT REFERRENCES

SINGAPORE REFERENCE PROJECTS LIST

- CABAG Changi International Airport (KohBrother & Samsung)

- Tiong Seng Pre-Cast Factory (TiongSeng)

- Bedok New Water Factory (GTMS)

- Botanic MRT Station (TAISEI)

- Caldecott MRT Station (TAISEI)

- Farrer MRT Station (TAISEI)

- New Fire Station at Tampines (GTMS)

- Palawan Beach LRT Station

- Colume(Interior) in Titanium (Samsung Hub)

- Nathan Road Bungalows (GTMS)

- SOK Condominium (Interior-Rich Link Construction)

- Resort World SentosaCasino Hotel (as Consultant)

- Designer Bungalow in LIC Stainless Steel

- Severall Primary & Secondary Schools

……and more

…Some Selected Projects Around The World

- Malta International Airport (Hangar)

- Hongkong International Airport (Extension Terminal 1)

- BAHAI Temple in Cambodia

- BAHAI Temple in Papua New Guinea

- BPIS Mosque in Brunei

- Pusat Latihan Polis Mosque in Langkawi,Malaysia

- IPI Casino & Hotel in Saipan,CNMI

- STIHL Factory in Qingdao,P.R.China(Zublin)

- Heidenhein Electronics in Beijing,P.R.China(Zublin)

- Brose Factory in Changchun,P.R.China(Zublin)

- Dream Centerin Shanghai,P.R.China

- CEO Development Tower in Beijing,P.R.China

- Several Bungalows in Frankfurt/Wiesbaden/Rhein-Main-Area,Germany

- Spanish Pavillonin Shanghai,P.R.China

- …….and more